Getting The Caster Manufacturer To Work

How Caster Manufacturer can Save You Time, Stress, and Money.

Table of ContentsNot known Details About Caster Manufacturer Our Caster Manufacturer StatementsHow Caster Manufacturer can Save You Time, Stress, and Money.Caster Manufacturer Can Be Fun For AnyoneOur Caster Manufacturer DiariesGetting The Caster Manufacturer To WorkWhat Does Caster Manufacturer Mean?

Hard rubber wheel wheels produce sound reduction as well as flooring defense. Rubber wheels with air inside that give optimal floor protection and the capacity to roll over diverse obstacles. Pneumatically-driven wheels supply padding and also stress and anxiety absorption, making it ideal for carrying sensitive tons over a variety of floor surfaces. Pneumatic caster wheels are well suited for aerospace and other applications.These non-marking, non-conductive wheels supply remarkable floor defense. Gray iron spreadings are made use of to make these wheels. The lots is routed to every face of the inverted angle iron track by the 90 grooves drilled right into the face of the wheels. V-Groove wheels can additionally be made use of to take care of the flow of a load over large distances in a selection of treatments.

One more advantage of this kind of brake is that the actuation technique can be performed with the feet, which removes operator stress from bending down to actuate with a hand. These brakes can be installed on a wheel's leading or tracking edge. Face call brakes work by pushing a plate onto the wheel's running surface area utilizing a threaded rod.

Everything about Caster Manufacturer

These brakes give a strong holding pressure as well as are suitable for durable applications. These brakes can be mounted on a caster's leading or routing edge. The negative aspect of this type of brake is that it calls for the operator to bend over and also tighten or loosen up the brake by hand, which puts extra stress on the driver and also takes longer than a foot actuated brake.

Securing and also unlocking these brakes is simple and can be made with the operator's foot. They also use up really little area because they are affixed to the caster's side and fit within the caster wheel's swivel span. The drawback of these brakes is that they do not have a great deal of holding power and so are much better suited for light-duty circumstances.

This phase will go over the applications and also benefits of wheel wheels. It will certainly also review the maintenance of wheel wheels.

Caster Manufacturer Things To Know Before You Buy

Durable wheels, on the various other hand, are typically seen in industrial plants, stockrooms, and other massive objects that require flexibility. Heavy-duty caster wheels are used to relocate hefty job things, assemblies, as well as devices in the aerospace as well as aircraft production process. Durable casters are a crucial part of airplane engine stands since they enable the professional to conveniently relocate and also secure the job stand.

Sturdy wheels can additionally be located on aviation hangar doors, which is a distinct application. Stiff durable casters for garage doors are readily available, they have to be able to take care of the weight of the large doors. The doors can be just moved by 1 or 2 people or by an automated button, thanks to these wheels.

The far better they are treated while they're under the health center's treatment, the a lot more likely they are to recover and also grow. This is why motion as well as particularly smooth mobility is so vital. Endless hrs laying in a health center bed while resting or waiting for a treatment to begin can be soul-destroying.

Some Known Details About Caster Manufacturer

Clients need to be rolled from the beds to surgery, recovery, and then back to the beds throughout the health center. Pneumatically-driven wheels are appropriate for situations with unequal or harsh surface or where the cart materials have to not be subjected to unexpected shock tons.

Because they can endure the unevenness of off-road surface, these wheels are ideal for applications that require both off-road as well as on-pavement procedure. Noise Attenuation: Decreases noise, which boosts working problems. As a result of the soft rubber walk and stress absorption ability of pneumatically-driven tires, they are additionally peaceful when in usage (Caster Manufacturer).

The flooring will not be harmed. The softer wheel safeguards floors from scratches and various other damage as well. Tires as well as casters reduce physical pressures and also demands on employees when moving large loads due to the fact that they advertise motion. Tires as well as wheels aid to speed up the motion of part as well as inventory within a plant, making storage space and production operations easier.

The Only Guide for Caster Manufacturer

On any type of grocery store or supermarket buying cart, wheel wheels can be seen at work. The wheels of the cart will generally turn with it, yet the cart framework does not have to move. The grocery store's wheels generate the least amount of resistance against the floor, and also the same holds true of the industrial wheels that make relocating any kind of large device or devices a lot easier.

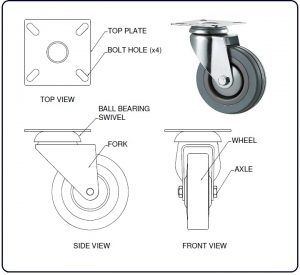

Because the caster wheel focuses on an axle as well as a bearing race, it undergoes much much less straight stress than a standard wheel. Due to the fact that the wheel moves as opposed to the framework when it transforms, the load bearing capability is far higher than a typical wheel. Another benefit of wheel wheels is that they come in a variety of shapes, sizes, and materials.

Before choosing if a pneumatic wheel is optimal for the application, there are a couple of things to think about, such as the amount of force needed to begin it rolling. The initial push force is greater as a result of the larger footprint as well you can look here as deflection of the air-filled tire. Due to the substantial footprint, swiveling the wheels is harder, and also the wheel will normally need a longer check that swivel lead.

Our Caster Manufacturer Ideas

An additional disadvantage of pneumatically-driven wheels is that they require more upkeep because air stress should be checked. Flats are typical with these wheels because they are conveniently punctured.

In the majority of situations, this requires lubing caster wheels and also the fittings every 6 months approximately - Caster Manufacturer. It's a great guideline to adhere to, and it must be a normal occurrence when all of a firm's casters and other components are checked, fueled oil, and also tested to guarantee they're in great functioning order.

Due to the fact that of the nature of numerous selections of wheels, they're typically made use of in unpredictable scenarios where they come to be wet. Other casters function with products that are extremely caustic on a routine basis.

Getting My Caster Manufacturer To Work

These crucial items of tools are vulnerable to damage, especially because they work against gravity each day in most locations. Every item with wheels need to be turned on its side once a month. Organization managers need to begin looking at the gear that connects the caster to the machine.

Anything that is jagged, used, or misplaced must be repaired or replaced asap. Minor flaws can steadily deteriorate a go to my blog wheel as well as necessitate its substitute in many cases, so it's important that they're attended to quicker as opposed to later on. Lubrication as well as fastenings are necessary, yet the caster wheel's stability is also essential.